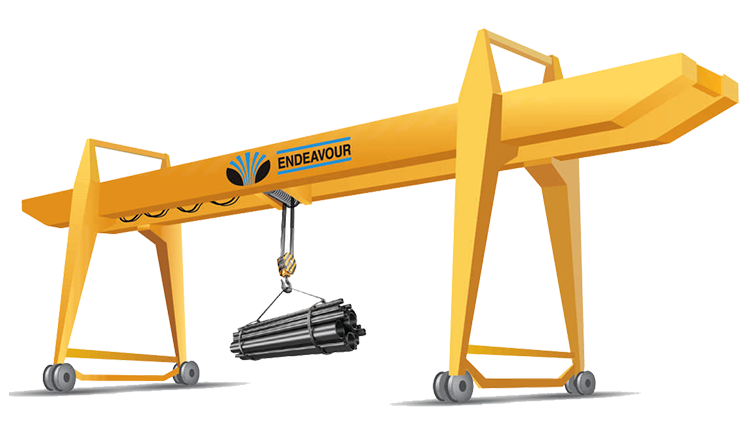

Maximize Efficiency and Load Capacity with Our Heavy-Duty Goliath Gantry Cranes for Industrial Applications.

These cranes are essentially the same as regular overhead cranes, except that the bridge carrying the trolley or trolleys is rigidly supported on two or more legs that run on fixed rails or other runways. A gantry crane features a hoist in a trolley that runs horizontally along gantry rails, usually fitted above a beam that spans between the legs, which themselves have wheels, allowing the entire crane to move at right angles to the gantry rails.

Gantry cranes come in various sizes, with some capable of moving very heavy loads, particularly the larger models used in shipyards and industrial installations.

- Capacity: Ranges from 1 ton to 150 tons.

- Ideal for: Primarily used in outdoor applications.

Type of Gantry Crane:

- Single Girder Gantry Crane

- Double Girder Gantry Crane

- Semi-Gantry Crane

- Manual / Portable Gantry Crane

- Full Gantry Crane

- Adjustable Gantry Crane

- Rubber-Tired Gantry Crane (RTG)

- Rail-Mounted Gantry Crane (RMG)

- Workstation Gantry Crane

Installation :

Goliath-Crane-01

Portable-Goliath-1.5-MT

Goliath-Crane-05

Goliath-Crane-7.5-MT

Applications:

Oil & Gas

Pharmaceutical

Logistics

Food Processing

Chemical

Cement

Packing

Mining

Frequently Asked Questions (FAQ):

A Gantry or Goliath Crane is a type of overhead crane that has a horizontal beam supported by legs at both ends. It operates on a runway or track installed at ground level, allowing it to move horizontally to lift and transport heavy loads.

- Shipping yards

- Ports and harbors

- Construction sites

- Steel mills

- Warehouses

- Outdoor storage facilities

- Bridge: The horizontal beam that spans the width of the crane and supports the hoist mechanism.

- Legs: Vertical structures that support the bridge and provide stability.

- Hoist: The lifting mechanism attached to the bridge for raising and lowering loads.

- End trucks: Wheeled assemblies mounted on the bridge that allow horizontal movement along the runway.

- Versatility: Suitable for outdoor and indoor applications, including uneven terrain.

- High lifting capacity: Capable of lifting heavy loads ranging from a few tons to several hundred tons.

- Accessibility: Can reach areas that are difficult to access with other types of cranes.

- Flexibility: Can be customized with various features such as adjustable heights and spans.

- Containers

- Machinery and equipment

- Construction materials

- Bulk cargo (e.g., sand, gravel)

- Steel beams and pipes

- Large fabricated structures

- Overload protection: Prevents the crane from lifting loads beyond its rated capacity.

- Emergency stop button: Allows immediate halting of crane operations in case of emergencies.

- Limit switches: Prevents over-travel of the crane along the runway.

- Anti-collision systems: Detects and avoids collisions with obstacles or other cranes.

- Safety barriers and warning signs: Alert personnel to the presence of moving cranes in the area.

Gantry Goliath Cranes can be powered by electricity, diesel, or hydraulic systems, depending on the application and environmental conditions.

Yes, Gantry Goliath Cranes can be customized to meet specific requirements regarding lifting capacity, span, height, and operational features.

Trust Signals:

- ISO 9001:2015 Certified: This proves that we are dedicated to quality management and keep on upgrading.

- Compliance with Industry Standards: Makes us follow the set industry regulations and laws thus producing quality products that are harmless.

- Our manufacturing facilities are modern and well-equipped with the latest technology and machines enabling effective production of quality goods.

- International Presence: Known worldwide as a reliable producer.